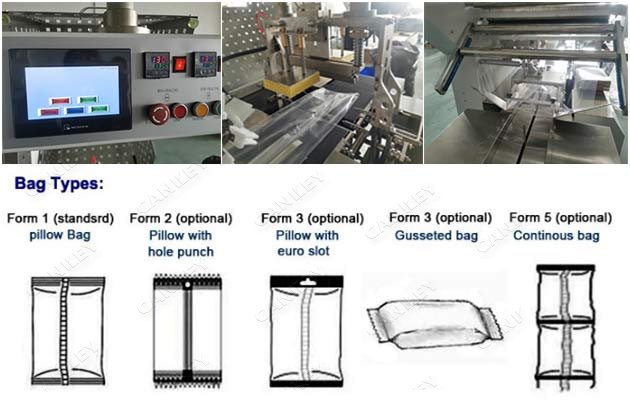

Features

Seaweednori snack packaging machineis controlled by dual frequency converters, the drive system is simple, reliable and easy to use. The packaging speed and bag length can be adjusted, good man-machine interface, easy operation, long lifespan.

Main Features of Nori Snack Packaging Machine:

♥ Dual frequency conversion control, Bag length can be set and cut in one step, saving time and film.

♥ Interface features easy and quick setting and operation.

♥ Self failure diagnosis, clear failure display.

♥ High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

About Nori seaweed packaging machine

About Nori seaweed packaging machine

※ Temperature independent PID control, more suitable for packaging different materials.

※ Positioned stop function, without sticking knife or wasting film.

※ Simple driving system, reliable working, convenient maintenance.

※ All control is realized through software, easy for function adjusting and technical upgrade.

这个缠绕包装机干roni流可以pack various kinds of regular objects like food, biscuits, pies, Muffins, chocolates, chocolate bar, candies, moon-cakes, instant noodle, cookies, rolls, egg rolls, wheat cracker, wafer biscuits, chocolate bar, bar soap, etc. We can customize the suitable one according to your requiredments or your products type.

Just Tell us: The Size of your products (Weight, Width, Height and Length) or Bag Size required.

Technical Data

| Model | CK-ZS450 | CK-ZS450X |

| Film width | Max 450mm | Max 450mm |

| Bag width | 50-180mm | 50-180mm |

| Product height | Max 80mm | Max 80mm |

| Film diameter | 320mm | 320mm |

| packing speed | 40-230bags/min | 40-230bags/min |

| Machine size | 4020*820*1450mm | 4020*820*1450mm |

| Weight | 1050kg | 1050kg |

Get Price

Get Price

E-Mail

E-Mail Whats

Whats TOP

TOP